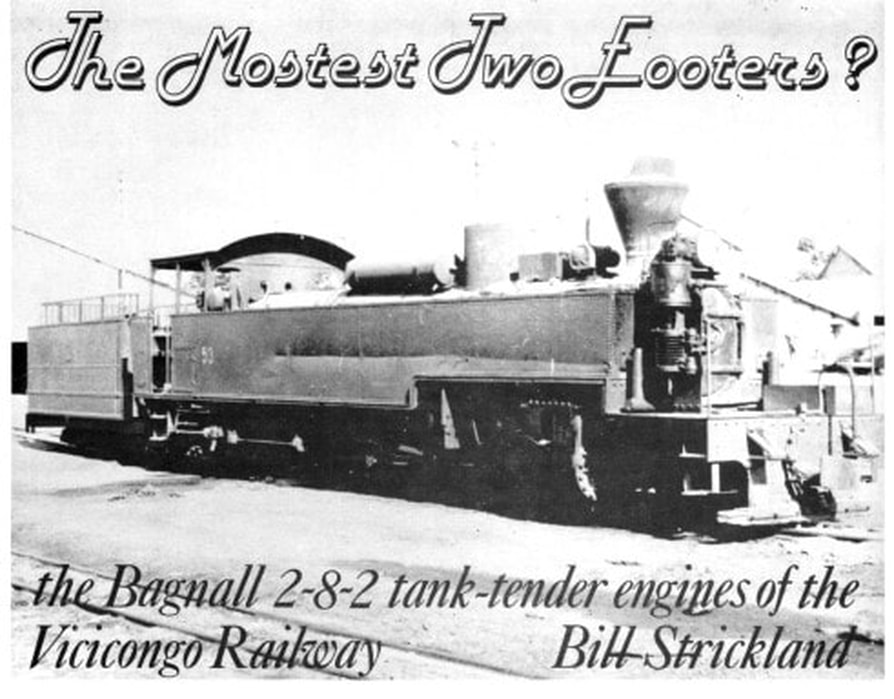

hile the Beyer Garratts of the South African Bellboys are generally acknowledged as the ultimate power in "Mighty Midgets", there are several types of tender engine which are actually larger; their own stable mates the NG 15 are almost six feet longer overall although their massive skirted tenders are almost as large as the engine itself. India also has a number of large engines both tank and tender types which have received due publicity in the specialist books and journals, although they have to vie for overall popularity with the smaller and probably most publicised of mountain goats, the "Darjeeling Tanks". But the title of the "Mostest Two Footer" must surely be accorded to the Bagnall tank—tender engines chitin ran on the Vicicongo Railway, an isolated line of the 60cm gauge, 521 miles long, almost in the centre of Africa in what was the Belgian Congo, now Zaire. Apart from its local importance it also provided an overland rail link between river navigation, in the Congo and Ulla valleys; in fact these engines were built for possible use hauling war supplies along this route (refs "Bagnalls Of Stafford", A.C. Baker 6 T.D.R. Civil, The Oakwood Press 1973 — o.o.p.). Apart from an article in the "Railway Gazette*, August 6, 1943 and a short history in John Day's "Railways Of Southern Africa", Arthur Barker Ltd 1963 — o.o.p., the chroniclers appear to have neglected this railway, probably due to its isolation. But railway of this size with its 10 chain curves and 1 in 66 gradients could surely provide anecdotes worth recounting; just how did No. 53 acquire that nasty crease along her right hand tank, no elephant did that. It could also be suggested that this led of publicity has also nullified possible interest by modellers, a great pity because for most of us producing scale models is the only way we can personally preserve some of the met interesting examples of different locomotive types.

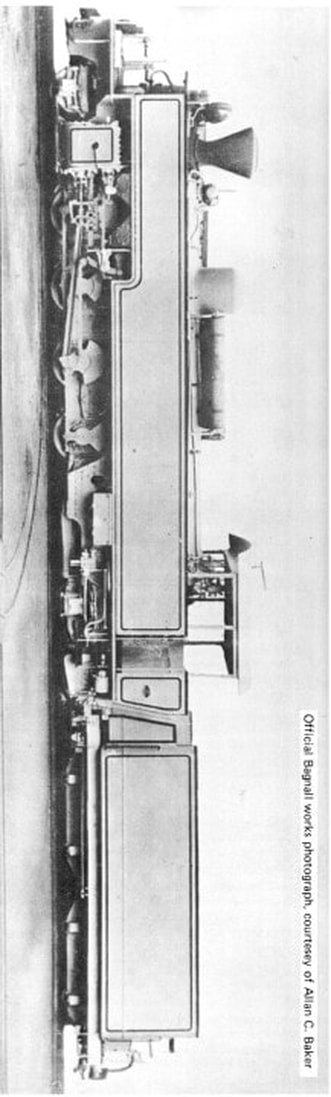

Built by Bagnalls of Stafford in 1942, these 2-8-2 engines at 56' 8½ " overall are just over eight feet longer than the Garratts. The most unusual feature is the water tanks on both engine and tender, the 1122 gallons carried on the engine normally being a valuable addition to the adhesive weight, choice of supply to the injectors being by two—way valves beneath the footplate on both sides, the tender capacity being 1100 gallons plus 247 cubic feet of wood fuel in the well and on top of the tank; water intake points average Mont 18½ miles apart. The cylinders are 15¾" bore by 17¾" stroke and the eight

Built by Bagnalls of Stafford in 1942, these 2-8-2 engines at 56' 8½ " overall are just over eight feet longer than the Garratts. The most unusual feature is the water tanks on both engine and tender, the 1122 gallons carried on the engine normally being a valuable addition to the adhesive weight, choice of supply to the injectors being by two—way valves beneath the footplate on both sides, the tender capacity being 1100 gallons plus 247 cubic feet of wood fuel in the well and on top of the tank; water intake points average Mont 18½ miles apart. The cylinders are 15¾" bore by 17¾" stroke and the eight

|

driving wheels at 3' 1 13/32" diameter are - I believe - the largest on any two foot gauge engine; even the rod work is big, the oil boxes on the main cranks hold over a pint of oil each. The frames, which are stepped out behind the rear drivers to accommodate the wide firebox are steel plate 23/32" thick, braced with plate stays between the driving wheels and steel casting at both ends with a heavy ribbed casting across the Junction of the main end rear frames; the cylinders are each cost integrally with a half saddle, these being bolted along the centre line. The boiler pressed to 170 p.s.i. Is 13' 3” between tube-plates by 3' 10 3/8” inside diameter at the front ring; the firebox - designed for wood fuel - has a grate area of 24.2 square feet end the total evaporative heating surface is 958 square feet. The 4' 1” diameter smokebox carries a large chimney with built-in spark arrester, also a 250 watt headlight. Standard equipment carried includes a pair of 20 ton traverse screw jacks and re-rail poles, It could be interacting to know how often these were actually used.

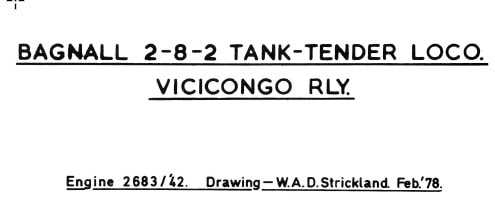

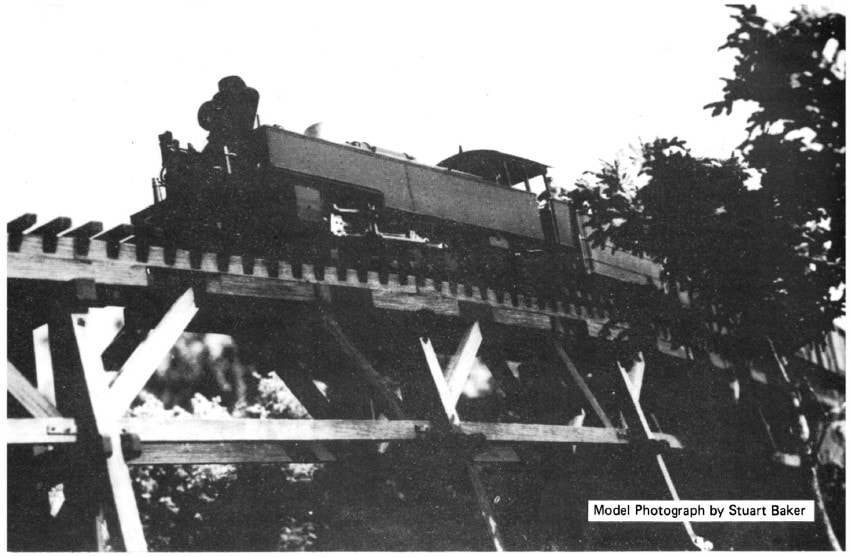

There le a lack of published information on these engines in service but with the Inevitable increase of diesel power the days of the wood burning steamer were very obviously numbered and when I read recently that 'there is no operational stem in Zaire today" that meant that perhaps we may never read of operational problems hauling 300 ton loads to those 1 in 66 grades at 28 m.p.h.. Meanwhile, I like to imagine that at least one got away, even if only et 1/36 full size, to continue pounding up the 1 in 50 grade on my garden railway hauling prototypical 300 ton loads. The model it 1/36 full size, the scale being .333" = 1 foot; this is an "exact" ratio of our 1' 11½” gauge to 16½mm or "00" gauge. Information and works drawings were generously loaned by Allan Baker - for which I am very grateful - and further thanks are due to colleague Fred Marris who made an excellent Job of the photo process work. As is customary with all my modelling I made a line drawing of the engine to 1” scale and another of the rod end motion work to 1½” scale; this assembling of essential information familiarizes one with the project as a whole and enables any forward planning of construction methods, motor mounting and drive mechanism, etc. to be sorted out and if need be drawn up at an early stage. In this particular case the 26 volt motor was too big end even when stripped and re-constructed the magnet only just fitted between the tanks with thous to spare, which meant that the firebox wrapper had to be cut away without it being obvious; the ideal gear ratio to provide a prototypical speed did necessitate a special gear which fortunately I am equipped to do; the provision of housings for ball races I make a practice of fitting where possible; these details aura finalised on a drawing, time well spent. |

The frames are .048" brass made as a matched pair; two spacers of 1/8" brass extend from 1/8" behind each buffer beam to the gap needed for the rotor and gears, the frame plates are screwed and finally sweated to the spacers leaving a "key seat" 1/4" deep along the top making a platform and very positive location for two 1/8" plates on to which the boiler saddles and body work are built and to which back plates for the buffer beams are brazed. The outer frames at the hind end ware made complete with all rivet and bolt head detail before pinning to spacers, one of which at the frame end is ribbed, and these sub-assemblies ware through pinned and sweated to the main frame assembly. After cleaning up the axle box guides ware finished to a "gauge" width, axle boxes fitted with axle centres checked with the vernier.

Driving wheels are my usual built up construction which produces an extremely strong fully insulated assembly. The tyres are stainless steel brazed to milled spoked centres which have sleeves 1/8" wide on the becks for the brushes, obviously one ensures that the number of spokes is correct. Tufnol sleeves are first epoxied and hot cured to the 5/32" dia axles and turned to accept the wheel centres, which are once again epoxied end hot cured. The assemblies are then finish turned on their own axles. The gear on the driving axle is a press fit after which the teeth ware given a "scrape" cut with a hob, the Tufnol sleeves being fitted after. Bogie wheels are similar being insulated both sides while the tender wheals have split axles 1/8" dia.

The boiler shall was machined from brass tube 3/16" thick bored at the front end for the smokebox which is a tubular plug with a wrapper embossed with correctly pitched rivet detail. The barrel rear end is shouldered to provide a seating for the .020" N.S. firebox wrapper which, after forming, was sweated in place and to a dummy bulkhead of 1/8" brass which seats on the cab footplate being secured by two screws through the rear "key" plate located in the main frame. Two saddles, one under the smokebox the other under the barrel, anchor the front end of the boiler to the front "key" plate, these plates being held in their locations by three screws, accessible from under the frames as they anchor the complete body assembly to the frames. Tanks and other plate work are .012" N.S. with the correct number of rivets pitched at 1 1/2" centres; the tanks are not a pair, the left hand one is tapered to match the boiler taper while the right hand one is parallel but stepped to clear the reach rod.

Complete cab detail is fitted. The actual backhead is a sub assembly carrying the water gauges, Injectors, regulator, etc., and is secured to the dummy backhead by one screw which is hidden when the firedoor is closed. Lubricators, steam end Westinghouse air gauges etc. are attached to the cab front sheet which together with the stem fountain form another sub assembly. Water cock handles and driver's air valves are attached to the cab side sheets while the reversing lever is anchored to the floor, which has a planked timber overlay. Boiler mountings include the big spark arrestor chimney, headlamp and generator, air tanks, safety valves, and of course the steam dome — and as this engine is "preserved" the dome is polished. The smokebox door is secured by the dart handle.

The cylinders are solid blocks secured from inside the frames by two screws each. A third screw locks the sleeve carrying the rear cover, stuffing boxes and slide bars. I adopted this construction many years ago end use it on all engines. This sleeve fits into a 3/16” reamed hole, right through and the valve spindle box and guide are part of second sleeve 1/8" dia. The front covers, that of the cylinder being ribbed, have spigots which are a press fit in the blocks. The outside cranks are 1/8" thick brass and are a press fit on their axles; crank pins are steel, shouldered and screwed 10 B.A. and are pulled up tight with a split collet tool. All rods are nickel silver, being cut from sheet up to 1/8” thick. Coupling rods are jointed and have gunmetal bushes, the connecting rod is fluted and bushed at the big end. The expansion links are built up in two halves with spacer blocks pinned through before sweating; die blocks are gunmetal and can be linked up from the weigh shaft which — however — is locked in forward gear, as connection to the reversing lever in the cab is well nigh impossible. The boxes of the third driving axle are locked as this axle has the gear, the leading two axles are equalised via the "springs" and their hangers, the trailing axle is sprung via the rear bogie equalising lever — the spring being housed between the double frames. Current pick up is from three pairs of wheels, there being no room on the geared axle for brushes.

Gears are 48 D.P. by 3/8" face width, the final gear having 34 teeth and the two intermediates 30 teeth — both of these running in 1/8" ball races. The primary gear is a composite as the centre is hobbed to mesh with the 1/16" pitch worm on the motor shaft; I use this idea when possible as It maintains a symmetrical layout with full width gears but Is only possible when the ratios are even. The motor is 28 volt with a 3/16" shaft.

Driving wheels are my usual built up construction which produces an extremely strong fully insulated assembly. The tyres are stainless steel brazed to milled spoked centres which have sleeves 1/8" wide on the becks for the brushes, obviously one ensures that the number of spokes is correct. Tufnol sleeves are first epoxied and hot cured to the 5/32" dia axles and turned to accept the wheel centres, which are once again epoxied end hot cured. The assemblies are then finish turned on their own axles. The gear on the driving axle is a press fit after which the teeth ware given a "scrape" cut with a hob, the Tufnol sleeves being fitted after. Bogie wheels are similar being insulated both sides while the tender wheals have split axles 1/8" dia.

The boiler shall was machined from brass tube 3/16" thick bored at the front end for the smokebox which is a tubular plug with a wrapper embossed with correctly pitched rivet detail. The barrel rear end is shouldered to provide a seating for the .020" N.S. firebox wrapper which, after forming, was sweated in place and to a dummy bulkhead of 1/8" brass which seats on the cab footplate being secured by two screws through the rear "key" plate located in the main frame. Two saddles, one under the smokebox the other under the barrel, anchor the front end of the boiler to the front "key" plate, these plates being held in their locations by three screws, accessible from under the frames as they anchor the complete body assembly to the frames. Tanks and other plate work are .012" N.S. with the correct number of rivets pitched at 1 1/2" centres; the tanks are not a pair, the left hand one is tapered to match the boiler taper while the right hand one is parallel but stepped to clear the reach rod.

Complete cab detail is fitted. The actual backhead is a sub assembly carrying the water gauges, Injectors, regulator, etc., and is secured to the dummy backhead by one screw which is hidden when the firedoor is closed. Lubricators, steam end Westinghouse air gauges etc. are attached to the cab front sheet which together with the stem fountain form another sub assembly. Water cock handles and driver's air valves are attached to the cab side sheets while the reversing lever is anchored to the floor, which has a planked timber overlay. Boiler mountings include the big spark arrestor chimney, headlamp and generator, air tanks, safety valves, and of course the steam dome — and as this engine is "preserved" the dome is polished. The smokebox door is secured by the dart handle.

The cylinders are solid blocks secured from inside the frames by two screws each. A third screw locks the sleeve carrying the rear cover, stuffing boxes and slide bars. I adopted this construction many years ago end use it on all engines. This sleeve fits into a 3/16” reamed hole, right through and the valve spindle box and guide are part of second sleeve 1/8" dia. The front covers, that of the cylinder being ribbed, have spigots which are a press fit in the blocks. The outside cranks are 1/8" thick brass and are a press fit on their axles; crank pins are steel, shouldered and screwed 10 B.A. and are pulled up tight with a split collet tool. All rods are nickel silver, being cut from sheet up to 1/8” thick. Coupling rods are jointed and have gunmetal bushes, the connecting rod is fluted and bushed at the big end. The expansion links are built up in two halves with spacer blocks pinned through before sweating; die blocks are gunmetal and can be linked up from the weigh shaft which — however — is locked in forward gear, as connection to the reversing lever in the cab is well nigh impossible. The boxes of the third driving axle are locked as this axle has the gear, the leading two axles are equalised via the "springs" and their hangers, the trailing axle is sprung via the rear bogie equalising lever — the spring being housed between the double frames. Current pick up is from three pairs of wheels, there being no room on the geared axle for brushes.

Gears are 48 D.P. by 3/8" face width, the final gear having 34 teeth and the two intermediates 30 teeth — both of these running in 1/8" ball races. The primary gear is a composite as the centre is hobbed to mesh with the 1/16" pitch worm on the motor shaft; I use this idea when possible as It maintains a symmetrical layout with full width gears but Is only possible when the ratios are even. The motor is 28 volt with a 3/16" shaft.

Bath bogies are built us to simulate the heavy castings of the prototype, the rear truck being particularly massive (the journals were 5.709" die by 1.51" long), both front and rear drawbars are pivoted on the bogie pivots and both trucks were sprung. The buffers are not strictly to prototype, which were very large, but the couplers wore Separate; my buffers are smaller end are slotted for choppers to comply with all stock on ay railway.

The front footplate carries a pair of 20 ton traverse screw jacks, clasped of course; the front buffer beam has two jacking points and are-rail teem along the bottom edge. Re-rail poles are also carried on the left hand tank.

The tender frames are 1/16" brass strip sweated to a shaped floor of .020" 0.5.. While the tank is correctly formed as a horse shoe with angle stanchions inside the upper plate-work it is almost completely hidden under the stack of wood fuel; like the engine tanks the material is .012 N.S. with correct rivet detail. front end detail includes hand brake, water cock handles end working footplate flaps; at the hind end the tall Filler is flanked by two 10 gallon oil drums secured by chains and of course the toolbox on the platform. The equalised bogies have Tufnol bolsters and the wheels have split axles so all eight wheels are used for current collection. Couplers, as on the engine, pivot on the bogie centres.

Performance: the prototypes were designed to haul "246 to 294 tons on a maximum gradient of 1 in 66 2/3 at a speed of 28 mph, depending on operating conditions". The model is gear-ad to run at 28 mph with the wick turned right up, i.e. on 28 volts. The normal load on my 1 in 50 grade is up to 320 tons, m train length of 20 feet of scale weight stock; this she comfortably hauls without slip at any speed from a 2 mph caul to maximum speed. Trains are always made up with the heaviest loads at the front to avoid possible derailment of the leading bogies on a curve, a problem not unknown on soma full sloe hill railways, but an easement is planned sometime when the sunshine returns. My railway la basically a 184 feet dogbone, a scale 11 miles; of this only two short sections of 16 feet and 24 feet are level, the remainder comprises two gradients - one at 1 in 60, the other 1 in 50, both climbing just over 12" between levels. Weather conditions can effect running of course, oxidised rail surface. which give engines a good grip also increase rolling resistance, particularly on curves, so "operating conditions" are far nose prototypical than running indoors, which of course adds to the interest.

Meanwhile, the "elephant prodder", in red livery with braes end cooper work polished as all preserved engines should be, takes her turn hauling any load offered - except the track cleaning chore, which is reserved now for the only engine which is capable of tackling it single-handed, the Bayer Garrett. G 16, mightiest of the midgets.