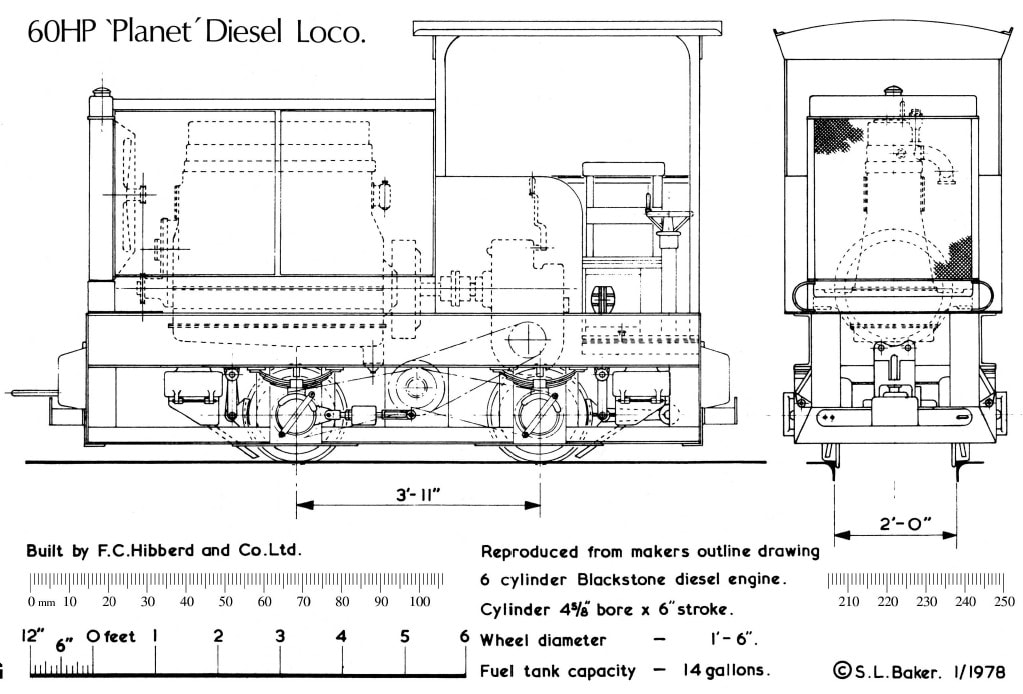

The Planet 60HP Diesel Locomotive

By Stuart Baker

The narrow gauge heavy oil locomotive illustrated was built by Messrs. F.C. Hibberd & Co. Ltd. for a gold field in Venezuela. The power unit consisted of a six cylinder high-speed Blackstone Diesel engine, capable of developing 60 BHP at a speed of 1000 rpm. The valves were operated by push rods and rocking levers, enclosed in dust and oil proof covers. Ignition of the fuel system was effected on the spring-controlled system, which was designed to function correctly at all engine speeds. Lubrication was by forced feed, the oil pump being of the geared type. A centrifugal governor checked the maximum speed of the engine, independent of the load. Cooling was effected by water forced through the cylinder jackets by a centrifugal pump. A large size radiator cooled by a fan, belt-driven off the engine crank-shaft, was fitted at the front end of the locomotive. Fuel oil was consumed at the rate of 0.4211b per BHP-hour. The engine was started by means of a single cylinder petrol (pilot) en3ine driving through a friction gear. A multiple disc dry plate clutch provided with special friction linings transmitted the power from the engine crank-shaft to the gearbox. The latter was designed for three speeds in either direction, namely, 4, 6.5 and 10.5 m.p.h., and was operated by one single lever, an arrangement which greatly facilitated speed changing and reversing. All spur and bevel wheels were of the helical gear type and in constant mesh. A pair of roller chains transmitted the engine power from the gearbox to a transverse lay-shaft arranged midway between the driving wheels, which latter were driven by another pair of roller chains. The latter and the sprocket wheels were enclosed in suitable casings. Correct tension of the roller chains was effected by a system of adjustable radiussing rods attached to the axleboxes.

The chassis was of the four wheeled type with an open frame, fabricated of rolled steel channel sections, plates and angle flanges. Gusset plates and bracings ensured satisfactory rigidity. The buffing and draw-gear consisted of a centre buffer-coupler fitted to each headstock; besides a spring fender was provided at either end of the locomotive. The chilled C.I. wheels were forced on to the steel axles. The axleboxes were fitted with roller bearings. A hand-operated screw brake and a sanding apparatus acted on all wheels. The electric lighting outfit consisted of a 12-volt C.A.V. generator driven directly off the engine shaft, a storage battery and switch gear. A horn was fitted for warning and signaling purposes.

The chassis was of the four wheeled type with an open frame, fabricated of rolled steel channel sections, plates and angle flanges. Gusset plates and bracings ensured satisfactory rigidity. The buffing and draw-gear consisted of a centre buffer-coupler fitted to each headstock; besides a spring fender was provided at either end of the locomotive. The chilled C.I. wheels were forced on to the steel axles. The axleboxes were fitted with roller bearings. A hand-operated screw brake and a sanding apparatus acted on all wheels. The electric lighting outfit consisted of a 12-volt C.A.V. generator driven directly off the engine shaft, a storage battery and switch gear. A horn was fitted for warning and signaling purposes.