Trevellas Quarry

CHRIS COOMBES TELLS THE STORY BEHIND HIS LAYOUT...

Trevellas Quarry (West of England Road Metal Co. until 1/4/49, St. Agnes Granite Co. until 1/3/34).

Gauge: 2ft (SW726518)

Gauge: 2ft (SW726518)

(1) 4wPM H? 1924 New (1)

(2) 4wDM MR 7115 1936 (a) (2)

(3) 4wPM MR 4748 ? New (3)

LM5 4wDM RH 210784 1941 (b) (1)

(2) 4wDM MR 7115 1936 (a) (2)

(3) 4wPM MR 4748 ? New (3)

LM5 4wDM RH 210784 1941 (b) (1)

(a) Ex Glasgow Corporation Housing Dept. (b) Ex ? by 1947 f. M.O.S.

(1) Scr on site 5/55 by MacSalvors

(2) To George Garside (Sand) Ltd. Leighton Buzzard Beds. by 5/55

(3) OOU 8/47 scr on site by MacSalvors 6/55

(1) Scr on site 5/55 by MacSalvors

(2) To George Garside (Sand) Ltd. Leighton Buzzard Beds. by 5/55

(3) OOU 8/47 scr on site by MacSalvors 6/55

Quarrying for granite started near Trevellas Coombe about 1850 when some unemployed tin miners obtained a take-note from the landowner. The quarry was small, initially, the stone being broken by hand and sold locally. The then landowner formed a company in 1920, the St. Agnes Granite Co., to develop the quarry. Objections from local residents forced the Granite Co. to build their crushing and screening plant in Trevellas Coombe. The plant was connected to the quarry on the cliff top between Trevaunance Cove and Trevellas Porth, by a 2ft. gauge tramway. This was horse-worked at first but later a Howard petrol loco was purchased. In 1934 the West of England Road Metal Co. bought out the Granite Co. The new owners increased the capacity of the plant by building a new crusher house, at the quarry, on the cliff edge. The tramway was re-laid, and a new set of screens installed at Trevellas Coombe. Further locos arrived both new and secondhand but the loco shed (built for the Howard) was not extended and the later arrivals were kept at the loading station or screens. The petrol Simplex was soon retired when MR 7115 arrived, and was 'put out to grass' being robbed for spare parts from time to time.

The quarry was worked by dumpers which took the rock to the crushers. After crushing the stone was tipped down a covered chute, loaded into skips and hauled round the headland to the screening plant. The entire output was sent out to a tipping dock and bunkers, further up the Coombe where lorries were loaded and took the stone up a dirt road to Barkla Shop on the Perranporth - St. Agnes Road. The West of England R.M. Co. became part of Amalgamated Road‑stone Corporation Ltd. in 1949. The only visible effect of the merger was a new name board and the repainting of the Ruston in 'Plant Yellow'. The quarry was closed in 1954 because it was uneconomic. The machinery was sold for scrap to MacSalvors of Redruth who had cleared the site by December 1955. If you should visit the St. Agnes area of Cornwall, you will, unfortunately, find no trace of the quarry or the tramway. Perhaps it was all a dream.... Or was it?

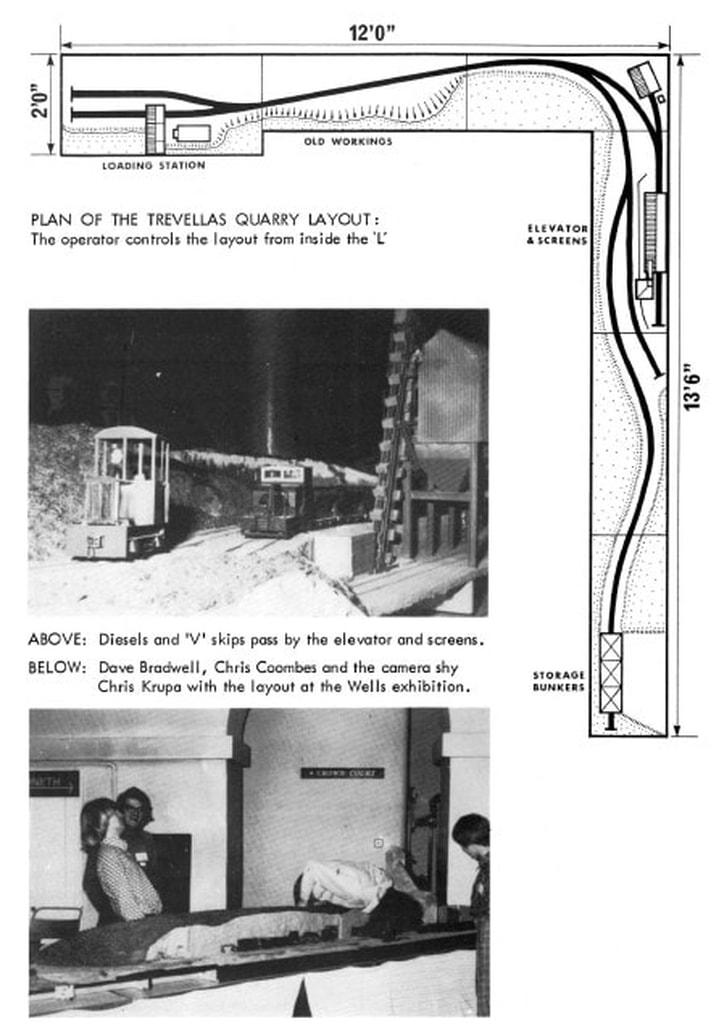

Now the factual bit. Trevellas was born out of a desire to salvage some tangible memory of those cliff top tramways operated in various Cornish roadstone quarries often in precarious and out of the way places. The complete layout measures 12ft. by 13ft. 6ins. on baseboards 18" and 24" wide, and is built to a scale of 16mm/ft (about 1/20th full size). Thus by using '0' gauge track, 2ft. gauge can be accurately represented. Track is '0' gauge fine scale rail soldered to printed circuit board sleepers and ballasted' with plaster earth mix and granite dust. The screening plant really works (well nearly always!) and is the result of three years experimentation. In particular the bucket elevator was easy to build but a s--- to get to work properly. The hoppers are tinplate and the frame is constructed from commercial Plastruct ABS sections clad in corrugated cardboard 'iron' and liberally sprinkled with granite dust.

Locos are mainly constructed from styrene sheet and Plastruct sections and two used Lima chassis which are ideal for I.C. Locos in this scale. Wagons are Triang Big Train tippers with sundry modification in the cause of realism and a repaint in Rust 'n' Crud.

To those accustomed to mainline operations, the method of working may seem unusual, but it must be realised that the railway was merely a method of transport operated for the convenience of the quarry. Thus the propelling of trains (especially empties) is the rule rather than the exception, and the loco is as likely to find itself in the middle of a train as at either end of it.

The quarry was worked by dumpers which took the rock to the crushers. After crushing the stone was tipped down a covered chute, loaded into skips and hauled round the headland to the screening plant. The entire output was sent out to a tipping dock and bunkers, further up the Coombe where lorries were loaded and took the stone up a dirt road to Barkla Shop on the Perranporth - St. Agnes Road. The West of England R.M. Co. became part of Amalgamated Road‑stone Corporation Ltd. in 1949. The only visible effect of the merger was a new name board and the repainting of the Ruston in 'Plant Yellow'. The quarry was closed in 1954 because it was uneconomic. The machinery was sold for scrap to MacSalvors of Redruth who had cleared the site by December 1955. If you should visit the St. Agnes area of Cornwall, you will, unfortunately, find no trace of the quarry or the tramway. Perhaps it was all a dream.... Or was it?

Now the factual bit. Trevellas was born out of a desire to salvage some tangible memory of those cliff top tramways operated in various Cornish roadstone quarries often in precarious and out of the way places. The complete layout measures 12ft. by 13ft. 6ins. on baseboards 18" and 24" wide, and is built to a scale of 16mm/ft (about 1/20th full size). Thus by using '0' gauge track, 2ft. gauge can be accurately represented. Track is '0' gauge fine scale rail soldered to printed circuit board sleepers and ballasted' with plaster earth mix and granite dust. The screening plant really works (well nearly always!) and is the result of three years experimentation. In particular the bucket elevator was easy to build but a s--- to get to work properly. The hoppers are tinplate and the frame is constructed from commercial Plastruct ABS sections clad in corrugated cardboard 'iron' and liberally sprinkled with granite dust.

Locos are mainly constructed from styrene sheet and Plastruct sections and two used Lima chassis which are ideal for I.C. Locos in this scale. Wagons are Triang Big Train tippers with sundry modification in the cause of realism and a repaint in Rust 'n' Crud.

To those accustomed to mainline operations, the method of working may seem unusual, but it must be realised that the railway was merely a method of transport operated for the convenience of the quarry. Thus the propelling of trains (especially empties) is the rule rather than the exception, and the loco is as likely to find itself in the middle of a train as at either end of it.